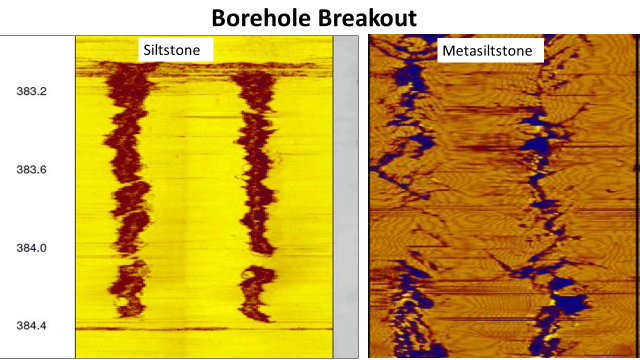

If the tangential stress at the borehole wall exceeds the tangential unconfined rock strength then the rock will fail in compression. In an even stress field this may cause total failure around the hole wall. More usually, the stress field around the borehole is not even, and if the stress is high enough, it will cause a localised line of spalling along the length of the hole wall. This spalling is readily detected by the use of an acoustic televiewer. The width of the spall zone may be detected with some accuracy in fine to medium grained sedimentary material and less so in coarser sedimentary or igneous or metamorphic materials, which tend to break in a more jagged manner. This is shown in the Figure below. The depth of spalling can be measured with much less precision. The orientation of the spalled zone is perpendicular to that of the major stress perpendicular to the hole.

In some cases where there is an extreme stress difference perpendicular to the borehole and sufficient fluid pressure exists within the hole tensile stress may be induced in the wall of the hole that exceeds the tensile strength of the rock. This leads to a tensile fracture on each side of the hole in the direction of the major stress.

The analysis of borehole breakout on its own is limited. In the first instance, the equations of stress around a hole cannot be completely solved for a linearly elastic rock using borehole breakout information alone. This applies even if the rock strength perpendicular to the borehole is known. Generally it is not.