Both these installations used a stress change cell cemented at several hundred metres depth in a vertical borehole. The cementitious grout used in the installation expands following its initial set so as to pre-load the stress change cells and permits it to measure stress relaxation.

Normally stress change devices would be installed in a hole where the initial state of stress has been determined by a stress measurement such as that through the Sigra IST system.

The stress change installations take three forms: uniaxial, biaxial+axial, and fully triaxial.

Uniaxial Stress Change

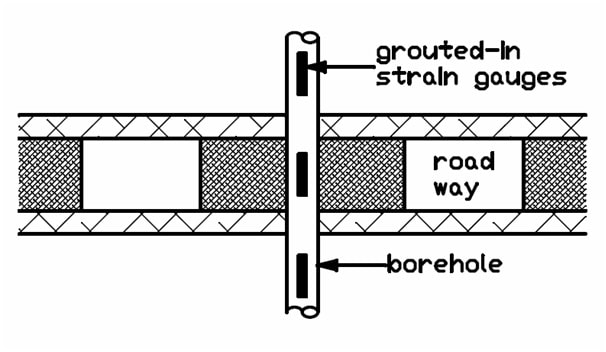

These installations involve cementing an axially strain gauged tube into a borehole and measuring the strain change and relating it to the in-situ stress change through the Young’s modulus and Poisson’s ratio of the surrounding rock. The prime use of the method is in determining pillar stress strain relations. Here the process is to cement axial stress change cells in the roof, pillar and floor. The roof and floor stress change cells yield a measurement of the stress and therefore load on the pillar, while the pillar gauge provides a strain measurement beyond the elastic range.

The load strain characteristics of the pillar may therefore be deduced from these measurements. These devices use vibrating wire strain gauges.

Biaxial + Axial Stress Change

These are a development of the uniaxial gauge and have in addition to the axial vibrating wire strain gauge, four transverse strain gauges. These enable the state of stress in the plane perpendicular to the gauge to be determined and therefore a more complete picture of stress to be determined.

Once again the determination of the state of stress is dependent on knowing the elastic properties of the rock in which the gauge is installed. These may be quite anisotropic in which case Sigra’s system for determining the triaxial modulus should be used.

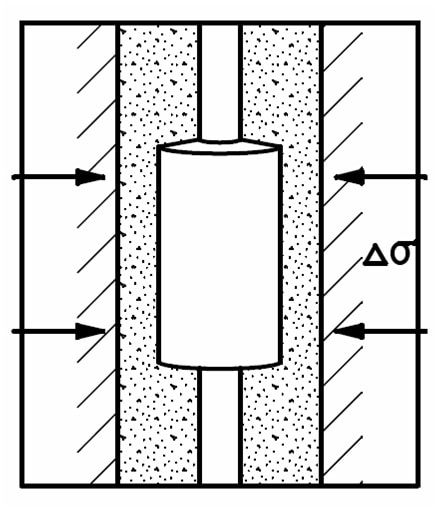

Fully Triaxial Stress Change

These also consist of a tube which is cemented into a borehole with an expanding cementitious grout. These are however fitted with electric resistance strain gauges and down hole amplifiers and A to D converters. These devices enable the fully triaxial state of stress change in rock to be determined.