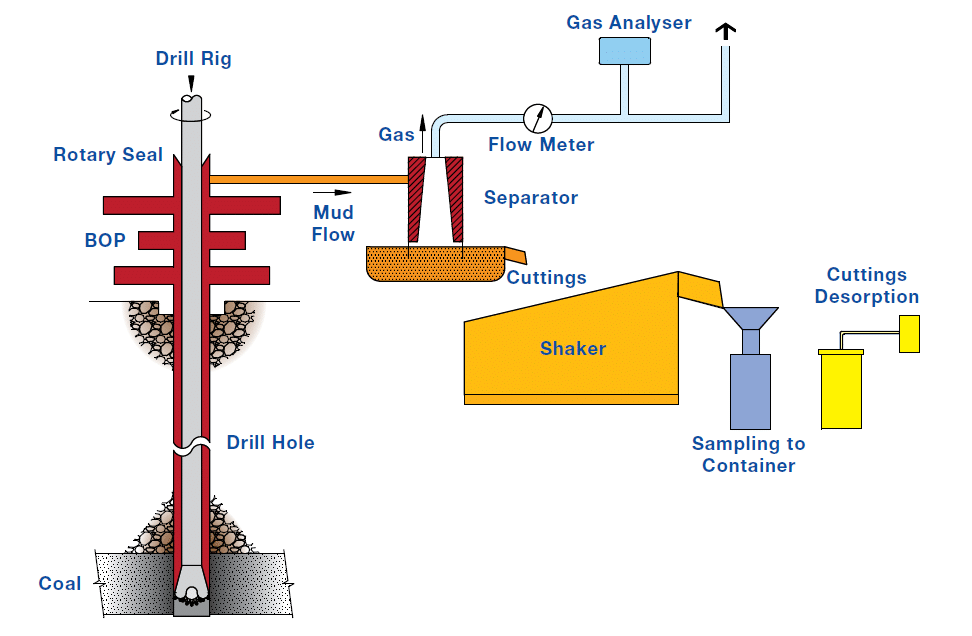

The gas released from the cuttings is collected from the separator and its volume and composition measured. The mud and cuttings pass from the cyclone. In high-flow operations, the mud and cuttings will move on to a shale shaker from which the cuttings can be sampled and tested using the same process as that described for chip desorption.

Figure 1 shows schematically the setup for this process. This is ideal for use on a production coal seam gas operation. It is also highly suitable for use on shales where core is expensive to obtain and disruptive to the drilling operation.

Following drilling, the hole should be geophysically logged to determine the volume and nature of the material drilled. By careful monitoring of drilling rate, depth and the mud flow rate Sigra can determine the origin of the cuttings. The method is inherently more accurate than core desorption because there is no reliance on lost gas determination – all gas released is captured. The use of the technique is reported by Gray, Singh and O’Brien (2013).

The typical applications for this are:

The system is not intended to replace gas content determination from core where this is targeting one or two well known coal seams or where core is required for other purposes. The system is however particularly useful in that it provides an absolute measurement of gas content through all the strata drilled.

The system can be installed on virtually any open hole rig that has a conventional mud handling system comprising mud tanks and a shaker. The additional equipment that is required comprises:

These are simple additions to most drilling operations.