Sigra uses pulsed DST testing in a different form. This is usually conducted as part of a multiple DST testing programme. This is particularly useful in determining anisotropy and separating it from inhomogeneity.

By increasing the number of locations from which fluid is withdrawn, it is possible to get more information on the mean permeability. If each of these wells is then fitted with a piezometer, it is then possible to obtain a directional permeability from the subsequent test well to the piezometer. This approach has the advantage that the test programme may be developed as each test is undertaken. This overcomes the normal problem with an interference test, of trying to determine what spacing to place piezometers from the pumping well before the testing has been undertaken. The use of a DST test for fluid withdrawal is convenient, because it may be conducted in slim core holes without the complications of setting up a pumping well.

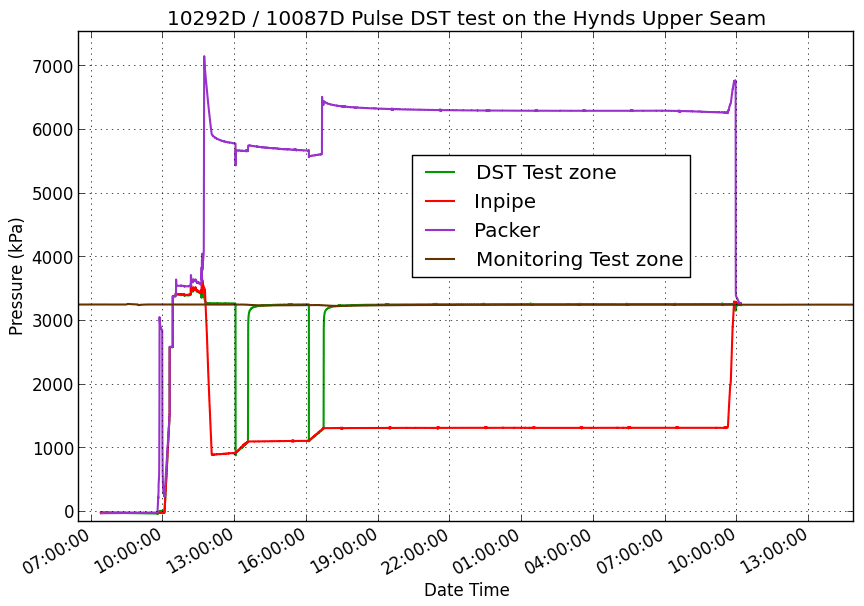

A hypothetical well layout is shown in Figure 1. This shows five test wells drilled and tested sequentially, and then each fitted with a piezometer. These produce five measurements of mean permeability and ten measurements of directional permeability. The five wells do not necessarily need to be drilled and tested. The process could be terminated sooner or extended, depending on how much information is required. The spacing of wells is dependent on permeability and storage parameters and is determined as the testing progresses. Figure 2 shows a characteristic DST test in one of the wells while Figure 3 shows the pulse received in an adjacent piezometer. This also shows the best fitted curve between well theory and the experimental data. The fit is very good and provides directional permeability and storage information.

Pulsed DST testing provides information on: