Native sorption isotherms are derived from core that is desorbing immediately after retrieval utilising the in-situ gas mixture. They therefore avoid problems associated with the mathematical recombination isotherms derived from multiple gas types.

The process is to take core directly from the core barrel and to place it in a water filled pressure vessel. The vessel is then sealed and the pressure is allowed to come to equilibrium. A small amount of fluid (water and gas) is then released and its volume measured before re-sealing and allowing the equilibrium pressure to be reached again. This process is repeated multiple times until a pressure close to atmospheric is reached. Gas samples are obtained for compositional analysis. The vessel is then opened, the coal mass, volume and residual water is measured and the coal is crushed to provide a Q3 volume. Samples are normally taken for moisture, carbonate and proximate analysis.

Determining a native sorption isotherm is a slow process. Mixed gas samples tested to date have taken 5 months to desorb adequately. Sigra can speed the process to fewer steps and with less time taken to approach equilibrium pressure at each step.

Sigra strongly recommend undertaking native sorption isotherm tests for all mixed compositional gas cases. The process provides a check on the combination of laboratory obtained isotherms using IAS theory.

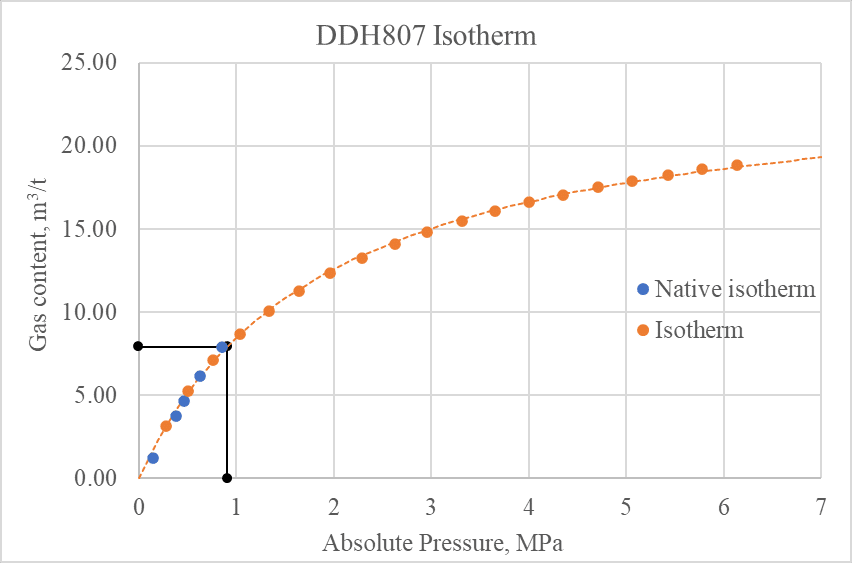

Figure 1 shows a laboratory isotherm with measured points in orange and a native isotherm with measured points in blue for a coal sample that is essentially methane.