Good site investigation is fundamental to any works in the ground, and the more complex the geology, the more intensive this exploration needs to be. Skimping on a full investigation raises the risk and will invariably cost more in the long term.

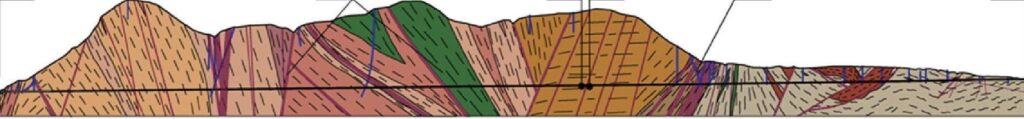

The choice of how to conduct a site investigation for a tunnel is very much dependent on the geology and how accessible the alignment is to the surface. If the geology is predominantly horizontally layered sedimentary rock, then the choice is logically to drill from the surface as the boreholes will pass through the stratigraphic sequence. This assumes that surface access is available and the tunnel is not too deep. If the geology is more complex with many varying features that will not be detected by vertical drilling, then near horizontal drilling should be used. This by its nature becomes a directional drilling operation.

Open hole drilling

Engineers tend to like core, but directional coring is very slow and provides small-diameter core. Open hole drilling can, in the right formations, be conducted very quickly and provide a lot of information. The use of a torque and thrust sub behind the drill bit can give a good indication of the rock type. This should be augmented by borehole geophysics.

There are a whole range of well-developed geophysical sondes that can be used. The basic ones are the full-wave sonic tool and an acoustic televiewer. The first to identify the rock modulus (and to some degree strength) and the second to find structural features. A number of other sondes can be used to help identify the rock type.

Getting geophysical sondes up a near-horizontal borehole needs to be done with a high level of confidence that they can be retrieved. This can be readily achieved by pumping the sonde out of the end of the drill rod string and retrieving the string and sonde together whilst logging. This minimises the risk of loss.

The use of directional drilling does not preclude the use of coring where the geology is unclear or from where samples are required. It is quite possible to complete an open hole and then pull back and cut the start of a branch, which can then be cored.

Horizontal holes may be tested for such important parameters as rock stress, permeability and fluid pressure.

The rock stress measurement may be conducted in several ways, depending on which is suitable for the situation. These include overcoring, hydrofracture, hydrojacking, the examination of the acoustic televiewer image for borehole breakout and the measurement of

core ovality. These tests can be conducted in horizontal holes.

Underground horizontal hole drilling and testing

The measurement of fluid parameters in the ground is frequently not well done. The packer test is overused and provides little information of any value. What is required is the real permeability, the natural fluid pressure and some indication of water storage within the ground. The ideal test and analysis process eliminates the problems of changing permeability near the well bore and enables the permeability of the rock mass to be determined with some indication of the extent of the measurement. These requirements are met by the correct testing methods that include drill stem tests and injection fall-off tests. These involve a period of pressure stabilisation, a flow period and then a recovery period when the test zone is shut in. These tests can be conducted in holes of any orientation.

The rock properties are important in any underground structure. So are the test methods that should be used to assess their behaviour. Anisotropy is often ignored and may control the behaviour of the underground opening. Why then do most test programs over emphasise uniaxial compressive and triaxial testing? The measurement of tensile strength and shear on planes of foliation or bedding is frequently more important in a design.

Learn More at the Australian Tunnelling Conference

Dr Ian Gray will be presenting on these important aspects of tunnel and cavern site investigation at the Australian Tunnelling Conference, held at UTS in Sydney on 6 May 2025.

Leave A Comment